A STORY OF THE 1960S

Industrial Frigo srl was founded in 1969 by the entrepreneur Penocchio Camillo; its first production site was launched in 1970 in Calcinato Brescia, over a surface of 2.500 sq. m.

The company built its experience in the cooling system and thermoregulation sector, achieving levels of know-how which today make it one of the world’s leading firms in the sector.

Passion

Passion for excellence, beauty and well-made

Sustainability

Which creates value in the long term

Ethics

Transparency and valorisation of people

Our products

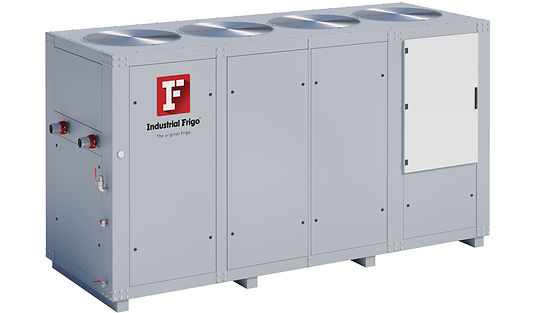

GR1A

AIR COOLED WATER CHILLER

The water refrigeration units of the GR1A series are monobloc units with air condensation, made in the version with internal tank (GR1AC) or for external storage (GR1AV), with the possibility of coupling multiple modules even with different power and at subsequent times. The GR1A series is particularly suitable for cooling plastic and rubber processing machines, die casting machines, galvanic systems, ceramic presses and many other industrial processes.

GR2A

AIR COOLED WATER CHILLER

The water refrigeration units of the GR2A series are monobloc units with air condensation, made with an internal tank at atmospheric pressure for centralized or dedicated cooling circuits. The GR2A series is particularly suitable for cooling plastic and rubber processing machines, die casting machines, galvanic systems, ceramic presses and many other industrial processes.

GTW

WATER COOLER WITH WATER CONDENSATION

The water thermo-refrigeration units of the GTW series are composed of a cooling section with water condensation and a thermoregulation section in the single-zone or double-zone version. They are particularly suitable for the conditioning of plastic injection press molds and many other industrial processes where thermoregulation is required with operating temperatures ranging from -5/+90°C. On request: Maximum Temperature +140°C.

VERSION WITH FREE COOLER WITH GLYCOL

VERSION WITH FREE COOLER WITHOUT GLYCOL

GRW C/V

WATER CHILLER WITH WATER CONDENSATION

The water refrigeration units of the GRW series are monobloc units with water condensation made in the version with internal tank (GRWC) or for external storage (GRWV), with the possibility of coupling multiple modules even with different power and at subsequent times. The GRW series is particularly suitable for cooling plastic and rubber processing machines, die casting machines, galvanic systems, ceramic presses and many other industrial processes.

GRW

WATER CHILLER WITH WATER CONDENSATION

The GRW series water refrigeration units are water-cooled monobloc units for dedicated installation. The GRW series is particularly suitable for cooling plastic and rubber processing machines, die casting machines, galvanic systems, ceramic presses and many other industrial processes.

GF1A

AIR COOLED WATER CHILLER

The water refrigeration units of the GF1A series are monobloc units with air condensation, made in the version with internal tank (C) or for external storage (V), with the possibility of coupling multiple modules even with different power and at subsequent times. The GF1A series is particularly suitable for cooling plastic and rubber processing machines, die casting machines, galvanic systems, ceramic presses and many other industrial processes.

GFA

AIR COOLED WATER CHILLER

The water refrigeration units of the GFA series are monobloc units with air condensation, made in the version with internal tank (GFAC) or for external storage (GFAV), with the possibility of coupling multiple modules even with different power and at subsequent times. The GFA series is particularly suitable for cooling plastic and rubber processing machines, die casting machines, galvanic systems, ceramic presses and many other industrial processes.

GRA

AIR COOLED WATER CHILLER

The water refrigeration units of the GRA series are monobloc units with air condensation, made in the version with internal tank (GRAC) or for external storage (GRAV), with the possibility of coupling multiple modules even with different power and at subsequent times. The GRA series is particularly suitable for the cooling of plastic and rubber processing machines, die casting machines, galvanic systems, ceramic presses and many other industrial processes.

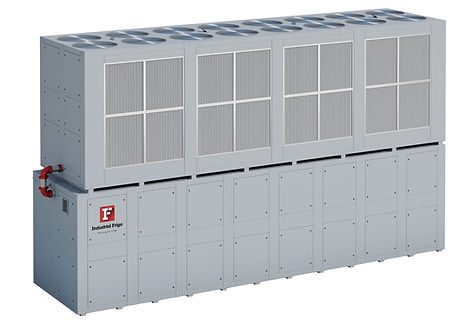

SIREG

INTEGRATED ENERGY SAVING AND GRAVITATIONAL DISCHARGE COOLING SYSTEM

The SIREG is a sophisticated process water cooling system with a single operating temperature, with fully automatic built-in freecooling; it can work with ambient temperatures from +45 °C to -25 °C and with process water without adding glycol thanks to the special safety system which prevents freezing in cold periods. The SIREG is built by combining the chiller with a cooling/free cooling system which allows to obtain high efficiency of the refrigeration cycle and in medium/cold periods, to produce cold water with considerable energy savings.

SIRE

INTEGRATED ENERGY SAVING COOLING SYSTEM

The SIRE is a sophisticated process water cooling system with a single operating temperature, with fully automatic built-in free cooling; it can work with ambient temperatures from +45 C to -25 C. The SIRE is built by combining a high efficiency chiller with a cooling/free cooling system which allows for high efficiency of the refrigeration cycle and, in medium/cold periods, to produce cold water with significant energy savings.

BRW

COOLING COILS

The BRW series cooling coils have been designed to create closed-circuit pressurized refrigeration systems capable of disposing of the heat generated in the various production processes without requiring water consumption and with minimal energy use. They are units composed of a heat exchange battery, a hydraulic circuit complete with pump, axial fans and the relevant control panel.

STANDARD DRY COOLER

ADIABATIC – PLASTIC

ADIABATIC – CARDBOARD

IFGA

AIR COOLED WATER CHILLER

The water refrigeration units of the IFGA series are monobloc units with air condensation, made in the version with internal tank (IFGAC) or for external storage (IFGAV), with the possibility of coupling multiple modules even with different power and at subsequent times. The IFGA series is particularly suitable for cooling plastic and rubber processing machines, die casting machines, galvanic systems, ceramic presses and many other industrial processes.

BRG

COOLING COILS

The BRG series cooling coils have been designed to create closed-circuit atmospheric refrigeration systems capable of disposing of the heat generated in the various production processes without requiring water consumption and with minimal energy use. They are units composed of a heat exchange battery specifically designed for automatic gravitational draining, a hydraulic circuit complete with external pump, axial fans and the relevant control panel.

STANDARD DRY COOLER

ADIABATIC – PLASTIC

ADIABATIC – CARDBOARD

DIF

AIR DEHUMIDIFIER

The DIF dehumidifier series produces a flow of air with low humidity content with an outlet dew point of -15 °C, preventing the formation of condensation on the mold surfaces. The dehumidification system consists of a high-efficiency desiccant rotor that absorbs the water molecules present in the air. A constant flow of hot, dry air passes through a portion of the rotor, extracting moisture from the rotor material and expelling it into the environment.

- Elimination of humidity on the mold (absence of waste) - Elimination of the risk of mold corrosion - Constant process in all climatic conditions - Reduction of cycle times and therefore increase in productivity.

UTA

AIR HANDLING UNITS

The UTA air cooling units can have various applications, including the cooling of blown film. Cooling water is provided from the centralized system or from a dedicated chiller.

UTA-GRAI-GRWI

AIR TREATMENT UNIT

They can be used in all applications where a controlled temperature air flow is required.

GRAI

AIR COOLED AIR CHILLER (single-zone or double-zone version)

The air refrigeration units of the GRAI series are monobloc units with air condensation, made in the version with internal tank for the supply of chilled water to the AHUs (air handling units) integrated into the structure. The GRAI series is particularly suitable for the cooling of blown plastic film extruders and for all those industrial processes where a flow of refrigerated air at a controlled temperature is required.

GRWI

WATER COOLED AIR CHILLERS (single zone or double zone version)

The air refrigeration units of the GRWI series are monobloc units with water condensation, made in the version with internal tank for the supply of chilled water to the AHUs (air handling units) integrated into the structure. The GRWI series is particularly suitable for the cooling of blown plastic film extruders and for all those industrial processes where a flow of refrigerated air at a controlled temperature is required.

OTA

DIATHERMIC OIL THERMOREGULATORS

The OTA series thermoregulation units are special units developed to allow thermoregulation with diathermic oil with maximum control. They were designed to condition molds and cylinders for various industrial processes, particularly in the plastics sector. They are units that can work up to a maximum temperature of 350 °C, with a single zone or multiple zones.

WTA

WATER TEMPERATURE CONTROL UNITS

The WTA series control units are special units developed to allow water thermoregulation with maximum control. They were designed to condition molds and cylinders for various industrial processes, particularly in the plastics sector. They are units that can work up to 95 °C, with a single zone or multiple zones. The heat exchange can be direct (standard) or indirect (optional).

The light version is available on request.

TW SERIES

- Alphanumeric display

- Compact frame

- Low pressure pump

- Optional indirect exchange

WTP140

WATER TEMPERATURE CONTROL UNITS

The WTP 140 series control units are special units developed to allow pressurized water thermoregulation with maximum control.

They were designed to condition molds and cylinders for various industrial processes, particularly in the plastics sector. They are units that can work up to 140 °C, with a single zone or multiple zones.

TWP Series

- Alphanumeric display

- Compact frame

- Low pressure pump

WTP160

WATER TEMPERATURE CONTROL UNITS

The WTP 160 series control units are special units developed to allow pressurized water thermoregulation with maximum control.

They were designed to condition molds and cylinders for various industrial processes, particularly in the plastics sector. They are units that can work up to 160 °C, with a single zone or multiple zones.

TC500

WATER THERMOREGULATION UP TO 18 ZONES

Thermoregulation unit for die-casting systems capable of providing pre-heating of the mold and precise and effective cooling of up to 18 zones by exploiting water evaporation. There are two possibilities of use.

- Cooling with water only

- Cooling with water and air

TC500 is available in the TCW and TCA versions.

TCW series: operation with water only; it is the most convenient solution for cooling medium-sized molds and where there are small diameter cooling channels.

TCA series: operation with water and compressed air; it is the ideal solution for cooling medium and large sized molds when the extension of the cooling channels is such that it does not guarantee good flow distribution. The joint use of compressed air and water guarantees a turbulent flow at every point of the mold and more effective cooling.

Certification for the installation, maintenance and repair of equipment containing fluorinated gases.

Did you find what you were looking for?

Fill out the form to define the next steps together!